Unlocking the Power of Remote Equipment Monitoring in Manufacturing and Industrial

Remote equipment monitoring is revolutionizing the manufacturing and industrial sectors. This article delves into its importance, the technologies driving it, and why AnyViewer is the best tool for the job. Discover the benefits of enhanced efficiency, predictive maintenance, and improved safety.

Introduction

In today’s fast-paced and ever-evolving industrial landscape, remote equipment monitoring has become a game-changer. Whether it's on the factory floor or in a sprawling industrial complex, the ability to keep tabs on machinery and equipment from a distance can revolutionize how businesses operate. This technology isn't just a nice-to-have; it's quickly becoming essential for companies looking to enhance productivity, reduce costs, and maintain a competitive edge. But what exactly is remote equipment monitoring, and why is it so important for manufacturing and industrial sectors? Let’s dive in and explore.

What is Remote Equipment Monitoring?

So, what exactly is remote equipment monitoring? In simple terms, it’s the use of technology to keep tabs on your equipment from a distance. Think of it as a high-tech babysitter for your machines, but instead of just watching, it collects data, analyzes performance, and alerts you to any potential issues. This way, you can address problems before they turn into costly breakdowns. From temperature and pressure to vibrations and energy consumption, remote equipment monitoring covers all the bases, ensuring that your operations run like a well-oiled machine.

Importance of Remote Equipment Monitoring in Manufacturing and Industrial Sectors

Why should you care about remote equipment monitoring in manufacturing and industrial settings? For starters, it’s all about efficiency. In industries where every second counts, the ability to monitor equipment in real time is invaluable. You can identify inefficiencies, optimize processes, and ensure that everything is running at peak performance. Plus, with the rise of Industry 4.0, where smart factories are becoming the norm, remote monitoring is no longer a luxury—it’s a necessity.

But it’s not just about keeping things efficient. Safety is another critical factor. Remote equipment monitoring helps you stay on top of potential hazards, ensuring that your workers are safe and that you’re in compliance with regulations. The financial component is important to consider. By catching issues early and scheduling maintenance before something goes wrong, you can save a ton of money in repair costs and avoid the dreaded downtime.

Key Components of Remote Equipment Monitoring Systems

To understand how remote equipment monitoring works, it's essential to break down its core components:

Sensors and IoT Devices

These are the building blocks of any monitoring system. Sensors attached to machinery collect data on various parameters such as temperature, pressure, vibration, and more. IoT devices then transmit this data to centralized monitoring systems.

Data Transmission Technologies

Data collected by sensors is transmitted to a central location using wired or wireless communication technologies. This could involve traditional networks, Wi-Fi, or even cellular connections in remote or challenging environments.

Monitoring Software and Dashboards

At the heart of the system is the monitoring software, which collects, organizes, and displays data on user-friendly dashboards. These dashboards allow operators to track equipment performance in real time, set up alerts, and generate reports.

Cloud Computing and Data Storage

With the vast amount of data generated, cloud computing plays a crucial role in storing, processing, and analyzing this information. Cloud-based solutions offer scalability, flexibility, and remote access, which are vital for modern industries.

Benefits of Remote Equipment Monitoring

The advantages of implementing remote equipment monitoring in manufacturing and industrial engineering are numerous and can transform how businesses operate. Let’s look at some of the most significant benefits:

Increased Efficiency and Productivity

By providing real-time insights into equipment performance, remote monitoring helps to optimize operations. This means machinery runs more efficiently, leading to higher productivity levels and less waste.

Reduction in Downtime

Any manufacturing or industrial operation's worst enemy is downtime. Remote monitoring allows for early detection of issues, enabling preventive maintenance before problems escalate, thus minimizing downtime.

Predictive Maintenance and Proactive Repairs

One of the standout features of remote monitoring is its ability to predict when equipment is likely to fail. This predictive maintenance approach reduces the likelihood of unexpected breakdowns and prolongs the lifespan of machinery.

Enhanced Safety

Monitoring equipment remotely can also enhance safety by reducing the need for personnel to be physically present in potentially hazardous environments. Automated alerts and shutdowns can prevent accidents and ensure compliance with safety regulations.

Cost Savings and ROI

While there’s an initial investment in setting up a remote monitoring system, the long-term savings are significant. Reduced downtime, lower maintenance costs, and extended equipment life all contribute to a solid return on investment.

How Remote Equipment Monitoring Works

Understanding how remote equipment monitoring operates can help in appreciating its benefits.

Sensors and Data Collection

The foundation of remote equipment monitoring in manufacturing and industrial engineering lies in the sensors installed on machinery. These sensors collect data on various parameters such as temperature, pressure, vibration, and more. After that, the data is sent to a central system for examination.

Data Transmission and Connectivity

Once the data is collected, it needs to be transmitted to a central monitoring system. This is where connectivity technologies like Wi-Fi, cellular networks, and even satellite communications come into play. These technologies ensure that data is transmitted quickly and reliably, regardless of the location of the equipment.

Analysis and Reporting

The real magic happens during the analysis phase. Advanced algorithms and software tools analyze the collected data to identify trends, detect anomalies, and generate actionable insights. These insights are then presented in easy-to-understand reports, allowing businesses to make informed decisions.

AnyViewer: The Best Choice for Remote Equipment Monitoring

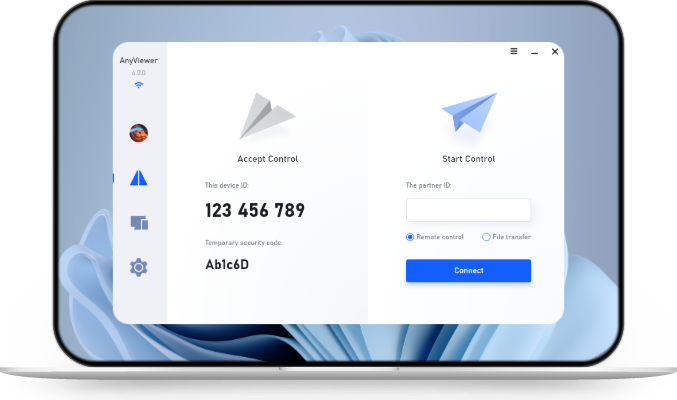

When it comes to remote equipment monitoring, choosing the right remote desktop software is crucial. That’s where AnyViewer comes in. With its robust features and user-friendly interface, AnyVieweris the go-to solution for businesses looking to monitor their equipment remotely. It offers real-time access to your systems from anywhere in the world, making it easy to stay on top of your operations no matter where you are.

It has a unique screen wall feature that allows users to easily monitor multiple computer monitors simultaneously from a central screen. This innovative feature simplifies the task of monitoring multiple devices simultaneously. With customizable screen configurations and seamless integration across preferred devices, users can easily and efficiently observe and manage screens, thus improving overall management efficiency.

But it’s not just about the features—AnyVieweris also incredibly easy to use. With its intuitive interface and quick setup, you’ll be up and running in no time. Alongside its ability to monitor and control screens in real-time, AnyViewer also provides a range of features like file transfer, mobile device control, screen sharing, and remote shutdown or restart. These tools make it an essential solution for remote workers who need effective management and support. Whether you’re a small business or a large enterprise, AnyVieweris the best choice for remote equipment monitoring.

Step 1. On both of your devices, start AnyViewer by downloading and opening it. Select the "Log in" option, then choose "Sign up" to create a new account. Make sure to use the same account on both devices.

Step 2. After logging in, your device will automatically sync with your active account.

Step 3. Navigate to the "Device" section, find your local device, and select "Screen wall."

Step 4. To begin, click the "Create screen wall" button.

Step 5. Select all the computers you want to monitor at once, then click "Add."

Step 6. You can now monitor the activities of all selected devices in one unified window, allowing you to manage them according to your needs.

- ★Tips: For the best performance when creating multiple screen walls, consider upgrading to the Professional or Enterprise plan. This will provide you with an enhanced experience for managing your desktops more efficiently.

Conclusion

Remote equipment monitoring in manufacturing and industrial settings is revolutionizing how businesses operate. By enhancing operational efficiency, reducing downtime, and improving safety, this technology is becoming essential for staying competitive in today’s market. With tools like AnyViewer, companies can easily implement and manage remote equipment monitoring systems, ensuring their operations run smoothly and efficiently. Whether you're aiming for increased productivity or better safety protocols, remote equipment monitoring in manufacturing and industrial environments is a powerful solution for modern challenges.