2025 Best Remote Access Software for Manufacturing

Remote access software has revolutionized manufacturing by providing real-time access to computers and systems from anywhere. This article explores the benefits of remote access tools, focusing on AnyViewer as the ideal choice for manufacturers.

Introduction

Manufacturing has entered a new era, one driven by technology and innovation. In today’s fast-paced industrial environment, manufacturers need to respond quickly to challenges—whether that’s equipment failure, process optimization, or quality control. One tool that’s making a massive impact? Remote access software for manufacturing companies. But what is it, and how does it help?

In simple terms, remote access software allows you to monitor and control machines or devices from anywhere. Whether you're overseeing a production line from your home office or troubleshooting an issue in a distant plant, remote access can save time, money, and headaches. Sounds pretty useful, right? Whether you need to monitor equipment, solve a technical glitch, or even coordinate with a team across the globe, remote access software makes it all possible with just a few clicks. Let’s dive deeper into how this works and why it’s a game-changer for manufacturing.

What is Remote Access Software?

Remote access software allows users to connect to systems, devices, and networks from anywhere in the world. In the context of manufacturing, this means that engineers, technicians, and managers can monitor machinery, troubleshoot issues, and even control factory operations without being physically present. Remote access software provides the necessary bridge to link central management systems to industrial equipment, leveraging real-time data to optimize performance.

The Evolution of Remote Access in Manufacturing

The transition from entirely on-site management to a hybrid model, where operations can be monitored remotely, was not without challenges. In the early days, manufacturers had to deal with limited internet bandwidth, unreliable software, and strict security concerns. As remote access technology evolved, these hurdles were gradually overcome with faster networks, more secure software, and the integration of IoT (Internet of Things) technologies.

Remote access tools have grown more sophisticated, allowing for seamless monitoring, predictive maintenance, and control, which has ultimately shifted the manufacturing industry toward smarter, more efficient operations.

Key Benefits of Remote Access Software for Manufacturing

There are numerous reasons why more manufacturers are turning to remote access tools. Let’s break them down:

- Efficiency Gains: Time is money, and downtime is one of the biggest threats to productivity in manufacturing. Remote access allows technicians and engineers to diagnose and fix issues faster, minimizing downtime and ensuring production keeps moving.

- Cost Reduction: Think about the cost of sending technicians to the site for every little issue. With remote access, much of the troubleshooting can be done from afar, reducing travel costs and labor hours.

- Flexibility: The modern workforce is more global and flexible than ever. Remote access lets experts from anywhere in the world lend their support, whether it’s for routine monitoring or urgent repairs.

- Real-Time Monitoring: You can track the status of machines in real time, anticipate failures before they happen, and adjust operations on the fly. This is especially useful in industries where small issues can snowball into major problems.

Common Features of Remote Access Software in Manufacturing

Remote access software comes with a variety of features that cater specifically to the needs of manufacturers, including:

- Device and Machine Connectivity: Seamless integration with factory equipment, sensors, and control systems.

- Security Protocols and Encryption: Ensures that all remote connections are secure, reducing the risk of data breaches and cyber threats.

- Remote Troubleshooting: Allows engineers to diagnose and resolve issues without needing to be on-site, saving time and minimizing disruptions.

- Data Analytics and Reporting Tools: Provides insights into production efficiency, machine health, and operational data, all of which can be used to make informed decisions.

How Remote Access Software Works in Manufacturing

Remote access tools typically operate by creating a secure connection between the user and the manufacturing equipment. Once connected, the user can view and control the system just as if they were on-site. The software leverages the internet or private networks to create these connections, ensuring that data transmission is both fast and secure.

Explanation of the Working Mechanism

After installing the remote access software on both the local and remote devices, the system uses encryption protocols to safeguard data as it travels between locations. This allows technicians to perform a variety of tasks—from adjusting machine settings to conducting detailed diagnostics—all from their laptop or mobile device.

AnyViewer: The Best Free Remote Access Software for Manufacturing

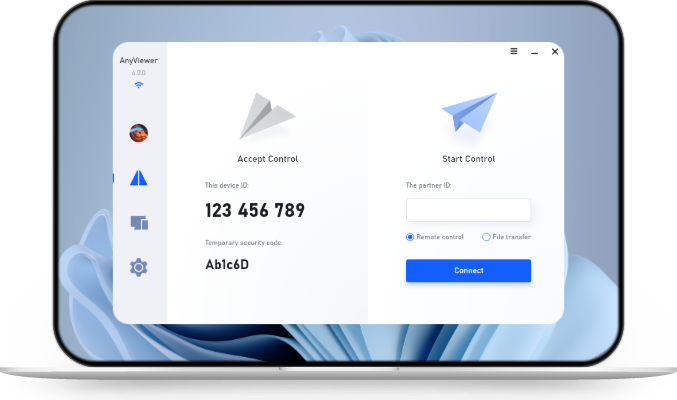

When it comes to remote access solution tailored for the manufacturing industry, AnyViewer stands out as the best choice. This powerful software provides seamless, secure, and efficient remote access to office computers, enabling manufacturers to monitor and control operations from anywhere. Its user-friendly interface allows teams to troubleshoot issues, manage equipment, and maintain workflow continuity without the need for on-site visits.

AnyViewer supports multiple devices, offers strong encryption for data security, and enhances operational efficiency by minimizing downtime. With its robust features and ease of use, AnyViewer is the ideal solution for modern manufacturing environments.

With AnyViewer, remote access and control become remarkably simple, no matter where you are, thanks to its seamless cross-platform compatibility. You can effortlessly manage Windows, Windows Server, and even mobile devices, all from one intuitive platform. Because of its intuitive design, people with different levels of technical proficiency can utilize it.

A standout feature of AnyViewer is its screen wall, which allows you to monitor multiple screens from a single, centralized display. This feature makes it easy to oversee numerous devices simultaneously, offering customized screen layouts and smooth integration across different devices to enhance management efficiency.

Beyond just monitoring, AnyViewer provides a range of essential tools like file transfer, mobile control, screen sharing, and remote shutdown or reboot capabilities. These features make it a comprehensive solution for remote work environments, ensuring smooth operations for businesses of any size. Whether you're managing a small team or overseeing a large enterprise, AnyViewer is the go-to option for reliable remote equipment management.

Step 1. Start by downloading AnyViewer on both devices and launching the application. Click on "Log in" and select "Sign up" to create a new account. Make sure you use the same account to log in on both devices.

Step 2. Once you've logged in, the devices will automatically sync under your account.

Step 3. Navigate to the "Device" section, find your local device, and click on "Screen wall."

Step 4. Click "Create screen wall" to begin the setup process.

Step 5. Choose the computers you wish to monitor simultaneously, then hit "Add."

Step 6. You’re now able to monitor all selected devices in one unified window, allowing for streamlined management across them.

- ★Tips: For the best performance when setting up multiple screen walls, it's recommended to upgrade to the Professional or Enterprise plan. These options provide advanced features and a smoother experience, enabling you to manage multiple desktops with greater efficiency.

Conclusion

In conclusion, free remote access software for manufacturing plays a critical role in improving operational efficiency, reducing downtime, and cutting costs. By allowing manufacturers to monitor and control equipment remotely, these tools help streamline processes and enhance productivity. Among the top solutions, AnyViewer stands out for its secure, user-friendly features, making it the ideal choice for managing manufacturing operations from anywhere. Whether you're troubleshooting issues or overseeing multiple systems in real-time, remote access software for manufacturing like AnyViewer ensures smoother, more efficient workflows in today’s fast-paced industrial landscape.