Tutorial: Remote Access for Plant Equipment and Assets

Remote access for plant equipment and assets is transforming industries by enabling real-time monitoring, faster troubleshooting, and enhanced decision-making. This guide explores how it works, its benefits, security considerations, and why AnyViewer is the best choice for reliable and secure remote access.

Introduction

In today's world, where industries are becoming increasingly dependent on advanced machinery and automated systems, remote access for plant equipment and assets is proving to be a game-changer. Imagine managing an entire factory's equipment, adjusting settings, or performing critical maintenance tasks without ever stepping foot inside the plant. Thanks to remote access solutions, that's now possible.

Remote access not only increases operational efficiency but also reduces downtime and maintenance costs. It allows plant operators and managers to monitor machinery, troubleshoot issues, and make adjustments from miles away. But how does it work? And why is AnyViewer the go-to solution for so many companies? Let's dive into this and much more.

The Evolution of Industrial Remote Access

The concept of remote access isn't new, but its application in plant operations has expanded. Initially, remote access was limited to basic data retrieval or troubleshooting. Over time, advancements in networking technology, cloud platforms, and Internet of Things (IoT) integration have transformed how we interact with plant equipment.

Why Remote Access for Plant Equipment and Assets is Essential

Why does remote access matter in today's fast-paced, tech-driven industries? Imagine trying to fix a machine issue at a distant plant site—without remote access, you'd have to send a team over. That's a huge waste of time and resources, right? With remote access, you can monitor systems, diagnose problems, and even implement fixes—all without setting foot on the plant floor.

In industries like manufacturing, oil & gas, and even healthcare, remote access for plant equipment and assets has become indispensable. It ensures round-the-clock monitoring and minimizes downtime by enabling quick troubleshooting. This technology is especially useful for industries with equipment spread across various locations, making traditional, on-site maintenance impractical.

Key Benefits of Remote Access for Plant Equipment and Assets

The benefits of remote access for plant equipment and assets go beyond just convenience. It fundamentally transforms how businesses operate, especially those with large, complex equipment setups.

Increased Efficiency and Productivity

One of the standout benefits of remote access is its ability to boost efficiency. By enabling operators to access equipment remotely, they can identify problems, adjust parameters, or even restart machinery without having to be on-site. This reduces response times and ensures that plant operations continue smoothly with minimal interruptions.

Cost Savings Through Remote Maintenance

Every minute of downtime can cost a plant thousands of dollars. With remote access, maintenance teams can diagnose and fix issues before they cause significant disruption. Remote diagnostics can also reduce the need for frequent on-site visits, saving travel costs and time. By implementing predictive maintenance strategies, plants can avoid costly breakdowns and extend the life of their equipment.

Enhanced Equipment Monitoring and Troubleshooting

Remote access systems allow plant operators to monitor equipment in real time. This constant oversight makes it easier to detect anomalies, which can be addressed before they escalate into larger problems. If a fault does occur, remote troubleshooting can quickly identify the root cause, reducing repair times.

Types of Remote Access Systems for Plant Equipment

Understanding the different types of remote access systems can help you select the best one for your needs.

Virtual Private Networks (VPNs)

VPNs have been a go-to solution for many industries. They allow secure connections between the plant’s internal network and external devices, ensuring that operators can safely access equipment from anywhere. By encrypting data, VPNs add an essential layer of protection.

Cloud-Based Remote Access Platforms

Cloud platforms are growing in popularity due to their flexibility. These systems enable plant operators to access equipment data from any device with an internet connection. With the added benefit of data storage and processing in the cloud, plants can easily scale their operations and integrate with advanced analytics tools.

Remote Desktop and Application Access

Sometimes, the easiest way to control plant equipment is through a remote desktop or specific applications designed for industrial operations. These systems mirror the experience of being physically present, allowing operators to control machines or run diagnostics as if they were on the plant floor.

Applications of Remote Access in Industrial Plants

Real-Time Monitoring of Plant Equipment

Remote access allows plant managers to keep a close eye on their equipment. With real-time monitoring, anomalies or performance dips are detected immediately. This helps prevent minor issues from escalating into major downtime events.

Predictive Maintenance and Asset Management

Predictive maintenance relies heavily on remote access. By constantly analyzing data from plant equipment, operators can predict when a machine is likely to fail. By being proactive, this strategy lowers downtime and avoids unplanned malfunctions.

Remote Control of Critical Equipment

Certain pieces of plant equipment are so vital that they need to be accessible at all times. Remote access ensures that these assets are under constant surveillance, and any critical adjustments can be made instantly from afar.

Overcoming Challenges in Implementing Remote Access

Cybersecurity Threats and Protection

While remote access offers numerous benefits, it also opens the door to potential cybersecurity threats. Unauthorized access can compromise equipment, leading to data breaches or even physical damage. It's crucial to put strong security measures in place, such as firewalls and encryption.

Connectivity Issues and Reliability

Reliable internet access is crucial for remote access systems. Any network disruption can hinder remote operations. To ensure continuous connectivity, plants often invest in high-quality, redundant internet services or use edge computing to process data locally when connections falter.

Employee Training and Adaptation

Introducing remote access systems may require training for staff to understand how to use these tools effectively. Proper education helps ensure smooth transitions and reduces the risk of operational errors.

How to Remote Access for Plant Equipment and Assets is Essential

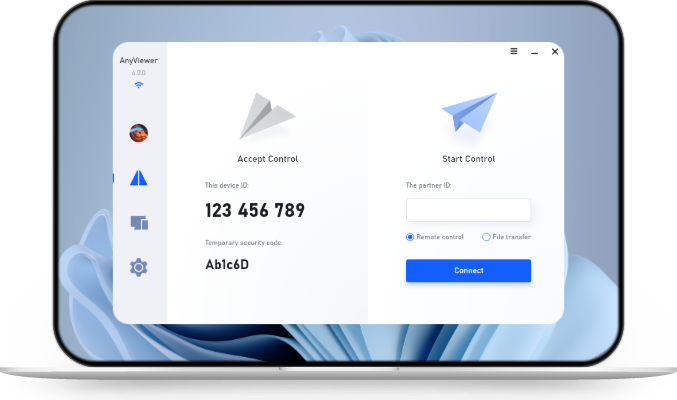

For seamless, secure, and efficient remote access to plant equipment and assets, AnyViewer emerges as the top choice for businesses seeking robust remote control solutions. Combining an intuitive user interface with high-speed, low-latency connections, AnyViewer ensures real-time access to critical systems, all while maintaining industry-leading encryption standards to safeguard sensitive data. Its versatile features include unattended remote access, screen sharing, multi-device support, file transfer, and real-time monitoring, which allow plant managers to troubleshoot issues, perform diagnostics, and manage operations from virtually anywhere.

Moreover, the software's easy scalability makes it suitable for both small facilities and large industrial plants, ensuring flexible integration into diverse environments. Whether you're looking to boost operational efficiency, reduce downtime, or enhance security, AnyViewer provides a reliable, high-performance platform that empowers your team to stay in control, no matter the distance.

Step 1. Begin by downloading and installing AnyViewer on both your local and remote devices. Head to the "Log in" section and choose "Sign up" to create an account by providing the required details.

Step 2. After logging in, your devices will automatically link to your account.

Step 3. Use the same credentials on both devices. Navigate to the "Device" tab, find the remote device you'd like to control, and click "One-click control" to enable unattended remote access.

- ★Tips: Upgrading to a Professional or Enterprise plan unlocks several powerful benefits, such as:

- Expanding unattended remote access by allowing more device assignments and offering a comprehensive list to track connection history.

- Boosting privacy with Privacy Mode, which obscures the screen and disables input on the remote machine.

- Streamlining large-scale device management by grouping devices for easier organization.

- Enabling the monitoring of multiple devices at once using screen walls for a multi-view display.

- Increasing efficiency with mass deployment tools for fast setup across numerous devices.

- ...

To enjoy remote access with the best picture quality, follow these steps:

Step 1. After setting up the remote device, use the mouse and keyboard to control it. During your session, go to the top-center toolbar, and click Image > Image Quality > Ultra HD Mode to enable UHD from home.

Step 2. Navigate to Image > Frame Rate > Up to 60 FPS to guarantee smooth, high-definition visuals.

Step 3. Go to Image > Color Mode > True Color for precise color accuracy using 4:4:4 chroma sampling. Now, you're all set to experience top-notch remote access with AnyViewer!

Conclusion

In conclusion, remote access for plant equipment and assets is revolutionizing industrial operations by enhancing efficiency, reducing downtime, and enabling real-time monitoring. It offers significant cost savings and ensures quicker troubleshooting from any location. AnyViewer stands out as the top solution, offering secure, reliable, and user-friendly remote control with features tailored for industrial needs. Whether you manage a small facility or a large-scale plant, AnyViewer empowers you with robust security and seamless functionality, making it the best choice for ensuring smooth operations across all your remote systems.